Quartz refractory material refers to a refractory material composed of amorphous quartz (quartz glass). Fused quartz refractory bricks are mainly used in melting low-alkali or alkali-free borosilicate glass pool furnaces.

Fused Quartz Refractory Bricks

Fused quartz refractory bricks are pure SiO2 refractory bricks that contain higher SiO2 content than silica refractory bricks. Its chemical composition is determined by the purity of the raw materials.

In fused quartz refractory bricks, there is actually a small amount of cristobalite or tridymite crystallized in the center due to the slow cooling rate. Quartz refractory bricks contain a large number of bubbles due to their high viscosity and poor clarification when melted. Some of the bubbles come from the gas generated by the reaction between graphite rods and SiO2.

The advantage of fused quartz bricks is good thermal shock resistance. This is due to the small expansion coefficient of quartz glass (the lowest among all refractory materials). Therefore, its thermal shock resistance is very good below 1000°C. Above 1000°C, thermal shock resistance decreases due to crystallization.

Its thermal conductivity is very good, and its thermal conductivity is higher than that of magnesia bricks. The mechanical strength is high due to the dense nature of quartz refractory bricks. In addition, when the quartz brick is eroded, it will cause little pollution to the glass liquid. Therefore, it is better to use quartz bricks as the structural material for the bottom of low-alkali or alkali-free borosilicate glass pool furnaces.

Quartz Ceramic Refractory Products

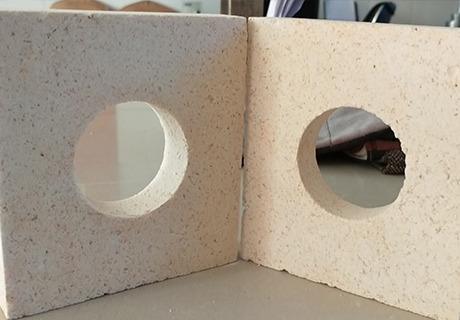

Fused quartz ceramic refractory products are refractory bricks made from quartz glass as raw material, which are crushed, batched, shaped, and then sintered at a certain temperature. Its chemical composition is SiO2 99.5%, most of which is glass phase, with only a very small amount of cristobalite crystals. The bricks are white and opaque.

Quartz ceramic refractory products have many excellent properties. If the thermal expansion coefficient is small, the thermal shock resistance is good. It has the characteristics of high viscosity at high temperature, high strength, strong slag resistance, and erosion resistance, low thermal conductivity, and small drying and firing shrinkage.

Fused quartz refractory bricks are used in alkali-free borosilicate glass pool furnaces and are a technological advancement for refractory manufacturers. It also provides protection for high-purity glass. To purchase high-quality silica bricks and fused silica bricks for glass kilns, please contact us.